Maintaining the Rink

No matter how well-groomed the ice rink, the ice will eventually be cut and pitted, and dust and bugs will dull it. The ability to quickly and effectively resurface the ice is as important to skating as the development of indoor ice itself.

The Raleigh arena has two Olympia ice-resurfacing machines, a Model 2000 and a Model 3000. The Olympia ice-resurfacers that MacMillan uses are powered by two propane tanks, and have V-8 Chevrolet engines and four-wheel drive. Each machine lasts about five seasons and provides more than 2,000 floods each year!

Advertisement

-- Charlie Brown

Ice-Resurfacing Machines

Before ice-resurfacing machines, ice rinks were resurfaced manually, using scrapers, towels, a water hose and squeegees. Resurfacing a regulation-size rink was time-consuming and labor-intensive. In the 1940s, Frank Zamboni began to experiment with building machines that would shave, scrape, wash and squeegee the ice surface all at once before putting down a fresh layer of water.

Early ice-resurfacing machines cost about $5,000 and were built by hand on war-surplus jeeps. Today, ice-resurfacing machines cost significantly more (about $55,000), are mass-produced, and every rink has at least one. Professional hockey teams, including the Carolina Hurricanes, routinely use two machines to cut down on the time needed to resurface the ice between periods. Most ice-resurfacing machines have a maximum speed of 9 to 10 mph (14 to 16 kph) and weigh between 5,000 and 6,000 pounds (2,300 to 2,700 kg)!

The NHL requires that two machines resurface the ice between periods. The ice is resurfaced before the game, after warm-ups, between periods, during playoffs, and when the game is over. With two resurfacing machines, it takes three minutes to complete the floor, each making four full passes up the ice. With one, it takes between six and seven minutes with eight full passes up the length of the ice.

The basic driving pattern is a clockwise motion of slightly overlapping ovals. MacMillan says that he uses 80 to 100 gallons (300 to 380 liters) of heated water between periods to resurface the ice. "With both machines," says MacMillan, "we can scrape about three-quarters of a bucket during each game."

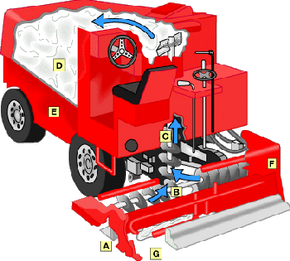

While MacMillan's Olympia machines have an 84-inch long, 1/2-inch thick blade, most Zamboni machines (like the one in this diagram) have a 77-inch long, 1/2-inch thick blade (A). The blade scrapes a 1/16-inch to 1/8-inch layer of ice off the ice surface. The blade runs the width of the machine and looks like a thick razor blade. The amount of ice taken off depends on the ice conditions. The rougher the ice surface (i.e., the more use it has had), the deeper the blade cuts.

Just above the blade is a horizontal, rotating screw, or auger (B). The auger gathers the shaved ice, or snow, and rotates it up to a vertical auger (C), where a spinning blade picks up the moving snow and throws it into the bucket (D). The bucket can hold an amazing 2,600 pounds (or 300 gallons) of snow!

Under the bucket, there are two tanks of water, one for "washing" the ice as it's shaved and one for making ice. As the resurfacing machine moves over the ice, the blade shaves layers of the ice off. Water from the wash-water tank (E) is pumped over to a cleaner (F) that blasts the water into the deep cuts in the ice and forces out dirt and debris. The excess water left on the ice is squeegeed off with a rubber blade (known as a towel) at the back end of the machine (G) and vacuumed up. The hot water loosens the crystal structure of the old ice underneath, so the new ice will form a solid bond with the old ice, instead of a separate layer that chips off easily.

The last step is to resurface the ice. Warm water from the second water tank is pumped over to the squeegee blade and spread evenly over the ice. This softens and fills in the deep cuts in the ice and helps to even out its surface.

After the final pass on the ice, MacMillan returns the machine to its garage. At this point, the snow bucket is raised and the snow is dumped into the snow pit. As the snow melts, the pit is drained.

Now that you know about ice rinks and ice-resurfacing machines, you'll never look at them the same again. On a hot summer day when you go to the arena, you'll understand why the building is so cool and how the ice stays frozen!

For more information on ice, ice rinks and related topics, check out the links below.

Ice Rink FAQ

How does an ice rink stay frozen?

Are ice rinks real ice?

Why is it called an ice rink?

How much does it cost to build an indoor ice rink?

Is ice skating dangerous for beginners?

Related HowStuffWorks Articles

- How Icemakers Work

- How Refrigerators Work

- How Air Conditioners Work

- How Snow Makers Work

- How Snowmobiles Work

- How Avalanches Work

- How Bobsledding Works

- How do they make the ice at an ice skating rink?

- How do they make clear ice?

- Why do they use salt to melt ice on the road in the winter?

- How much ice would I have to store up in the winter if I wanted to air condition my house all summer?

- How does dry ice work?

More Great Links

- Carolina Hurricanes

- Resurfice Corp. - ice resurfacing machines

- NHL Rulebook

- NHL Kids' Site

- RINK Magazine

Please copy/paste the following text to properly cite this HowStuffWorks.com article: